Introduction

After wines receive their final adjustments of sulfur dioxide, oxygen and carbon dioxide, they are typically filtered in-line on their way to a packaging or bottling line. As the wine is filtered to the desired level in this process, any surface the wine comes into contact with after the filtration process (including hoses, fittings, fixtures, the rinser and the filler, right up to the closure attachment or insertion where the wine bottle/package is sealed) must be cleaned and sanitised to prevent microbial or other contaminations.

The equipment from the filtration unit to the rinser and filler is typically connected as a closed system with cleaning, sanitation and sterilisation occurring together. Any maintenance or changing of this equipment set-up after sanitation requires re-sanitation of the affected area or in some cases re-sanitation of the whole line.

Typically, if only one bottling line exists, dry white wines are filtered and packaged first, followed by off-dry white wine styles, then dry red wines and finally sweeter red wine styles, before cleaning and sanitation is required to be repeated.

Detergents, cleaners, surfactants and sanitisers

A detergent or cleaner is a water-soluble cleaning agent which combines with dirt or breaks down deposits to make them more soluble. Detergents can include acids, bases (alkaline chemicals), surfactants, chelating agents and proprietary blends. Soaps are not used as they leave residues. Detergents or surface spray cleaning agents containing chlorine-based agents or artificial flavours (e.g. citrus/lavender) should be avoided to prevent chlorophenol, chloroanisole and artificial flavour taints transferring to the wine.

Surfactants, or surface-active agents or foaming or wetting agents, are organic molecules that have both hydrophobic (water-repelling) and hydrophilic (water-attracting)properties. They reduce the surface tension of water and thus help prevent biofilms forming on surfaces by facilitating contact between the detergent and the surface being cleaned. Surfactants are often used on the moving parts of bottling lines such as conveyor belts.

Chelating agents are chemicals that are used in hard water to bind minerals which might otherwise prevent surfactants from being effective. These can also be important when using hard water for steaming, as otherwise mineral deposition can occur on machinery, reducing efficiency.

Sanitisers are chemicals or treatments that kill microorganisms. Wineries define sanitation as a 3 log or 99.9% decrease in cell number. Typical winery sanitisers include hydrogen peroxide and peroxyacetic acid (peracetic), sulfur dioxide, alcohol solutions, hot water and/or steam. Different agents may not all be compatible with all surface types; for example, hot water or steam can damage some types of plastic equipment.

Alkaline solutions

Caustics solutions such as sodium hydroxide (caustic soda), sodium carbonate (soda ash) or potassium hydroxide (caustic potash) are commonly used in wineries. Caustics added to water to pH>9 are excellent detergents, with the higher pH lowering the surface tension of water, making the water feel soapy and helping it to better remove fats, proteins, colour material and crystalline deposits. High pH cleaners also kill microorganisms by disrupting cell wall functions. Formulations from 0.5-2% are used, often in warm water, for cleaning times around 15-20 minutes. Note that these agents can be corrosive to stainless steel and fittings, particularly at higher concentrations. Metasilicates are alkaline compounds that are non-caustic. Sodium ortho- and meta-silicates have detergent properties while being less damaging to equipment. A citric acid rinse (usually 0.6%-1%) should be applied for five minutes following cleaning with alkaline solutions, to neutralise the pH.

Traditional caustic soda products are gradually being replaced with formulated products to improve user safety, reduce requirements for PPE or storage of dangerous goods, reduce cleaning times and to improve environmental performance. Use of formulated products can reduce both the volume of water and volume of chemical required as well as the volume of water sent to wastewater treatment.

Quaternary ammonium salts (QUATS)

QUATS are ammonium-based sanitising agents which function by entering the cell membrane of microorganisms and disrupting cellular functions, causing cell death. They have differential activity toward different yeasts and bacteria, and limited activity against spores. QUATS are non-corrosive, non-toxic and non-irritating, are active over a broad pH range and have some residual activity after treatment. Rinsing is required after treatment. Common applications are to control mould growth on the exterior of tanks, walls, floors and in drains.

Acidulated SO2 solutions

Potassium and sodium metabisulfite solutions (10%), which release molecular sulfur dioxide, can be used to spot-sanitise parts of bottling lines or equipment. Acid-adjusted solutions use lower rates of potassium metabisulfite (100-200 mg/L) with 3 g/L citric acid (pH 2-3). Note that these solutions are both corrosive (sulfurous acid) and volatile and can cause respiratory irritation, and thus must be used in well-ventilated areas, used away from metal surfaces, and are not used to flush hoses or parts of the bottling line equipment.

Peroxides

Peroxide solutions are strong oxidisers that break down to generate singlet oxygen radicals or superoxide. Hydrogen peroxide exists as 3-30% solutions. Solutions >5% are strong irritants that can cause burns and blisters on exposed skin. Solutions rapidly break down with time. Thus weak solutions are usually used for removing excess sulfur dioxide from wines rather than as a sanitiser in this form.

Sodium percarbonate is a more stabilised powder form containing hydrogen peroxide, and breaks down to oxygen radical, water and sodium carbonate.

Peroxyacetic acid (peracetic acid) is more stable and less corrosive than hydrogen peroxide while remaining an effective oxidant even at low temperatures. It breaks down to acetic acid, hydrogen peroxide and water, has minimal foaming, and thus does not require rinsing after treatment. Peroxyacetic acid concentrations vary in proprietary products and should be used at recommended supplier rates.

Steam/hot water

Sterilisation of hoses, stainless steel equipment and fittings/fixtures is usually achieved with hot water at 80ºC for a minimum of 30 minutes. The sanitation period or hold time begins once the water temperature has been achieved at the furthest point from the filler, typically just after the filtration unit. There are a variety of proprietary materials that can be used to indicate if the temperature has been reached across all parts of an area being sanitised, including digital and infrared thermometers, steam test strips and tape used for autoclaves, or temperature indicator labels. Steam used to sanitise tanks or lines is applied until condensate forming on valves reaches >80ºC for more than 20 minutes. Hot water can cause deterioration of plastic or rubber components such as o-rings, hoses or impellers in pumps.

Ozone

Ozone is a strong oxidiser and an effective sterilant against a range of microorganisms and spores. It is, however, a strong irritant to the eyes, ears, nose, throat and lungs, with prescribed maximum exposure levels and monitoring required. It also requires specialised equipment and must be generated on-demand as it rapidly breaks down to molecular oxygen.

UV light

Water used for rinsing parts of bottling lines, filler heads, or for pushing wine batches through the packaging lines is often passed through a UV light treatment to ensure inactivation of any water-borne microorganisms.

Alcohol solutions

Alcohol is a good contact sterilant which kills microorganisms on contact, but it is also a combustible material. Wineries use diluted concentrations such as 70% w/w ethanol or isopropyl alcohol, which equates to an 80% v/v solution. This is used to spray onto surfaces after breakdowns and left to dry before resuming processing, to ensure surfaces remain sanitised.

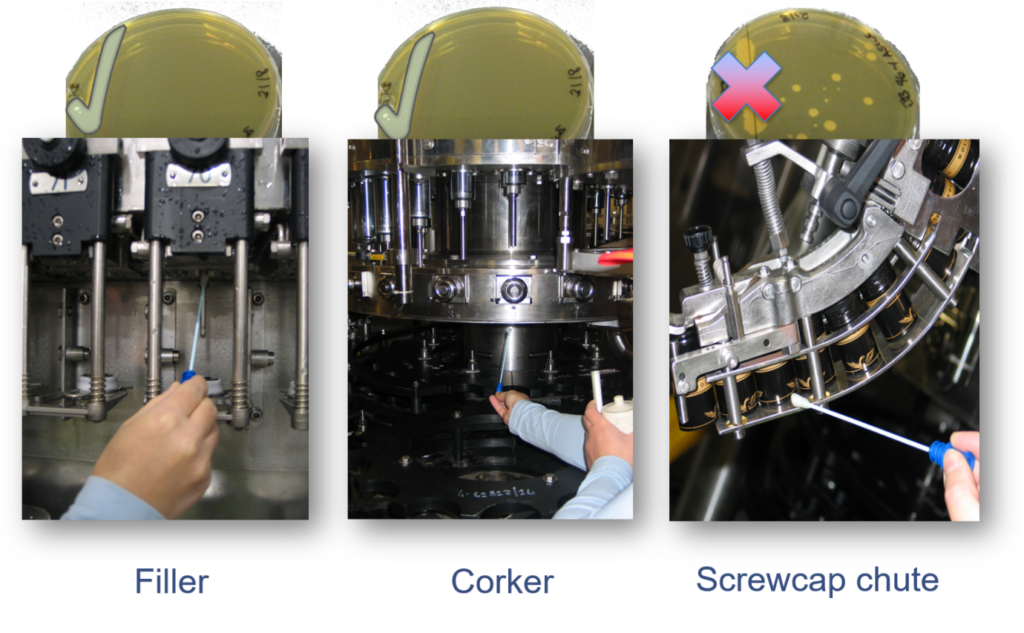

Biofilms

Biofilms are formed when one or different types of microorganisms first attach to surfaces and then grow, multiply and produce extracellular components (polysaccharides, exopolymer coatings) which form protective gel-like films or slimy layers that protect cells underneath from sanitising agents. Before a surface can be effectively sanitised, these films must first be removed with cleaning operations such as scrubbing, brushing or high-pressure treatments. Biofilm formation can be minimised or limited by using effective design, regular maintenance (e.g. replacing O-rings regularly), avoiding build-up of corker jaw grease, and limiting dead spaces in lines where biofilms could form.

Typical bottling line sanitation regimes

A typical historical bottling line sanitation regime would be to apply a caustic rinse, followed by a citric rinse to neutralise. Hot water at 80°C for 30 minutes would be a final sterilisation step. Some producers use a caustic rinse followed by a peroxyacetic acid rinse, then hot water. In order to remove caustics, some have replaced them with metasilicates.

Caustic, citric, hot water rinse exiting a filler head |

Hot water sterilisation/steaming of an enclosed rinser and filler packaging line |

Cleaning in place (CIP) programs

Sanitation programs may include options for sanitation at the start of the day or bottling operation, at the end of the day to leave equipment ready for bottling the next day, weekly sanitation and/or chemical wash operations, or when changing from bottling red wine to white wine. Sanitation programs generally begin using a cold and/or warm water wash.

When line stoppages and maintenance occur, any part worked on should be spot-sanitised. For longer breakdowns >4 hours, a re-sanitation process should be considered.

Cleaning hoppers

Chutes for closures should be cleaned and sanitised with alcohol or alternatives on the internal area.

Bottling line buffer tanks

The filler basin or bowl should be cleaned and sanitised at the end of the bottling process.

Testing sanitation operations

A regular monitoring strategy should be employed to check the effectiveness of the sanitation steps taken. Microbiological techniques used to monitor for spoilage microorganisms include membrane filtration methods for liquid samples, and swabs or ATP residue testing to test dry surfaces.

Traditional membrane filtration or swabbing methods have been retrospective, in that any non-conformances are identified several days after a wine has been bottled. Some molecular methods such as ATP testing, however, can give results in seconds.

ATP residue test

Bioluminescence methods can be used check for the presence of adenosine triphosphate (ATP). ATP is generated by all cells as an energy function and is used as evidence of the presence of living microorganisms. The method uses enzymes that react with ATP to produce light which can be read with a photosensitive detector. The technique is quick but does not differentiate between the types of microorganisms that may be present.

Swabbing

Swabbing involves using sterile pads to test sanitised areas of the bottling line, then placing them inside a sterile housing, often containing a sterile liquid solution. This solution, or sometimes the swab itself, is then plated onto growth media to measure any growth. If the sanitation process has been successful, no growth of microorganisms should be observed, similar to the example below. If growth is observed, then the packaging run should be put on hold until the packaged wine can be tested for possible contamination.

Areas commonly swabbed are post-filtration, rinser and filler heads, closure applicators, hoppers, ball cock valve seals. Affinity Labs offers microbiological audits of packaging lines. The audits involve testing bottling lines for sterility at critical control points (CCPs) to help identify potential risk areas that could lead to contamination problems.

References

Fugelsang, K.C., Edwards, C.G. 2007. Chapter 9: Winery cleaning and sanitizing. Wine Microbiology: Practical Applications and Procedures. Second Edition. Springer, US.

Gardner, D.M. 2016. Making cleaning and sanitation practical for the small commercial winery. Penn State Extension Wine & Grapes (October): https://psuwineandgrapes.wordpress.com/2016/10/21/making-cleaning-and-sanitation-practical-for-the-small-commercial-winery/

Iland, P., Grbin, P., Grinbergs, M., Schmidtke, L., Soden, A. 2007. Microbiological Analysis of Grapes and Wine: Techniques and Concepts. Patrick Iland Wine Promotions Pty Ltd.

Solis, M.d.A.A., Gerling, C., Worobo, R.W. 2015. An in vivo study: Sanitation of wine cooperage with five different treatment methods. Pract. Winery Vineyard (April): 58-63.