A bentonite fining trial is conducted to determine the rate of bentonite addition needed to ensure the heat stability of a wine. Because the positive charge on proteins is stronger at lower pH values, the effectiveness of bentonite is greater in wines with lower pH values. If it is intended to adjust the pH and titratable acidity of the wine, then this should be carried out prior to bentonite fining, since stability might be different under the new pH conditions.

Preparation of 5 % w/v stock solution for laboratory fining trials

Weigh 5 g bentonite into a dry 50 mL beaker. Measure approximately 85 mL of distilled water into a 250 mL glass beaker. Heat the water to approximately 60°C. While stirring, slowly sprinkle the bentonite into the water to disperse it thoroughly. When all the bentonite is added, allow the suspension to cool. During this period the bentonite will swell; normally the suspension is left to stand overnight. If the bentonite is not well dispersed, the suspension might need to be heated a second time. The suspension is then made up to volume with distilled water in a 100 mL volumetric flask and mixed well. It is important to note that the same batch of bentonite should be used in both laboratory trials and the cellar. Additionally, the bentonite suspension should be prepared under conditions as similar as possible to those in the cellar; with respect to water, water temperature, composition and time of rehydration before use.

Conducting and assessing the laboratory trial

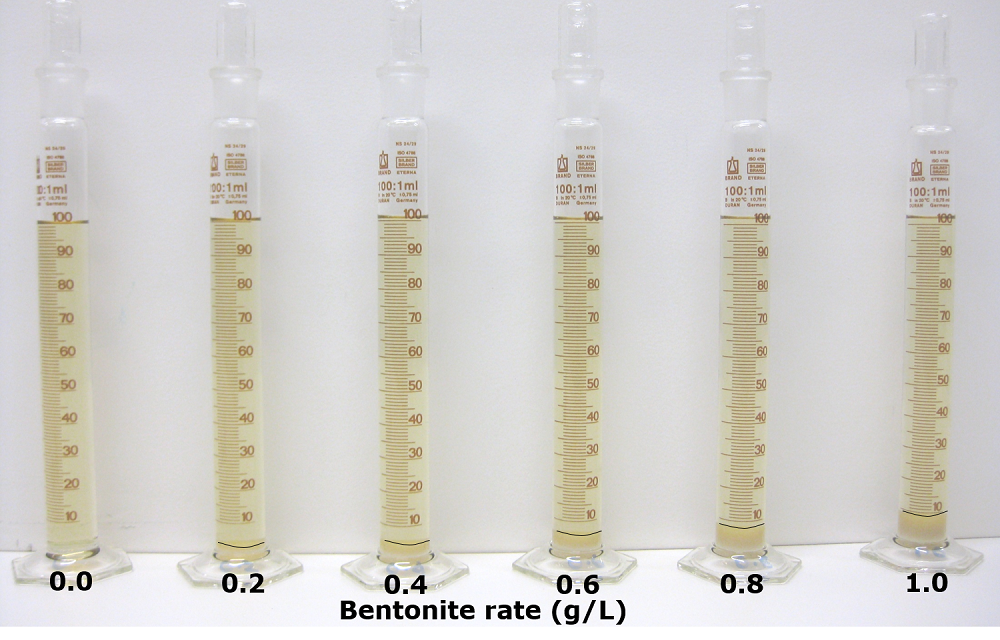

An addition of 1 mL of the 5% w/v stock solution added to 100 mL of wine represents an addition rate of 500 mg/L. To calculate addition rates, access the AWRI Fining Trial Calculator. Typical bentonite addition rates trialled are between 0.1 and 1.0 g/L (100-1000 mg/L). Small incremental additions (100 mg/L) are common or alternatively an initial trial can be conducted covering a wide range of bentonite additions to determine the appropriate rate of fining to achieve protein stability, and then repeating the trial at lower increments around this rate. The trial is commonly done using 100 mL measuring cylinders and adding incrementally increasing amounts of bentonite with a graduated pipette. Cap the cylinder and mix by inverting the cylinder a number of times. Allow the mixture to settle until the solution begins to clear leaving the lees in the bottom of the cylinder. This is generally 1-2 hours or sometimes overnight.

Example of a bentonite fining trial with incremental addition of 0.2 g/L bentonite, after two hours of settling. Note the increasing amount of lees at the higher rates.

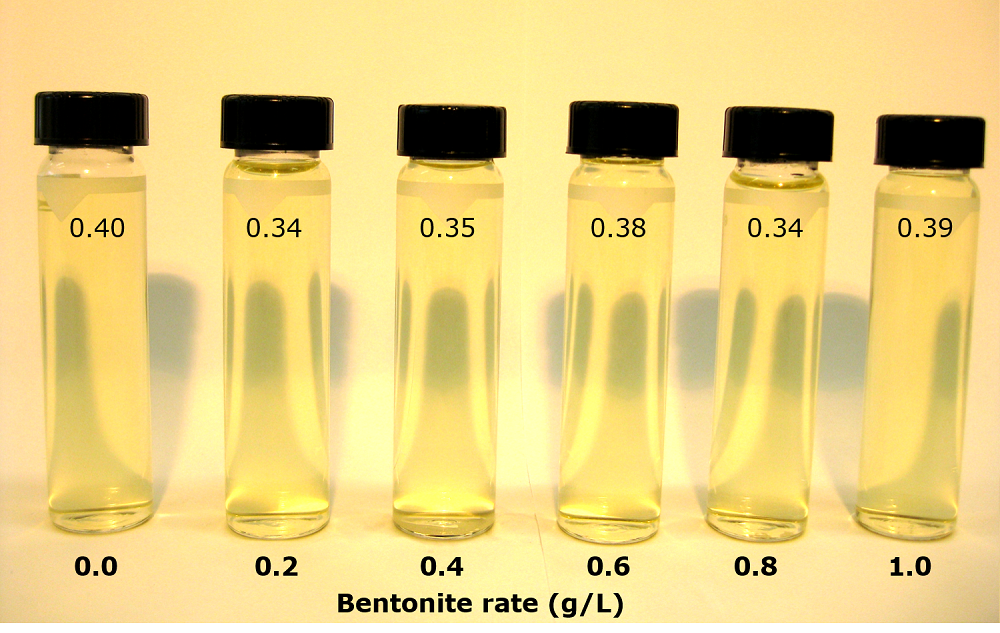

An alternative approach to clarifying the sample after bentonite fining trials is to centrifuge a 50 mL portion of the sample at 3,500 rpm for 5 minutes. Each fining rate sample is filtered through a 0.45 µm filter membrane into a glass turbidity tube or test tube ready for the heat test. The samples must be filtered to achieve a turbidity reading <2.0 NTU, or so the samples contain no visible haze, before conducting the heating step described below.

Example of the bentonite fining trial samples filtered into turbidity tubes. The NTU reading of each sample is displayed. All samples are visually clear and <2.0 NTU.

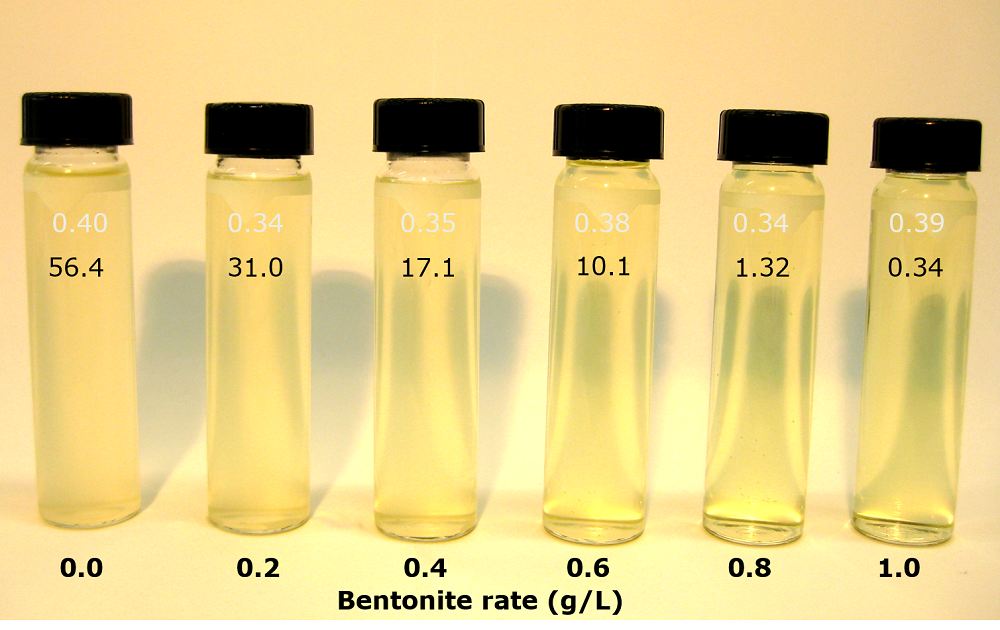

Heat the samples in the same manner as detailed in the heat stability test, cool for 3 hours (or overnight depending on the preferred heat test method) and then assess for visible haze or measure turbidity. Higher bentonite rates should achieve incremental increases in clarity as per below, as the bentonite removes more of the protein from the wine.

Example of the bentonite fining trial samples after heating. The NTU reading of each sample after heating is shown, compared against the turbidity of the samples before heating. The greater the NTU after heating, the more heat unstable the wine sample.

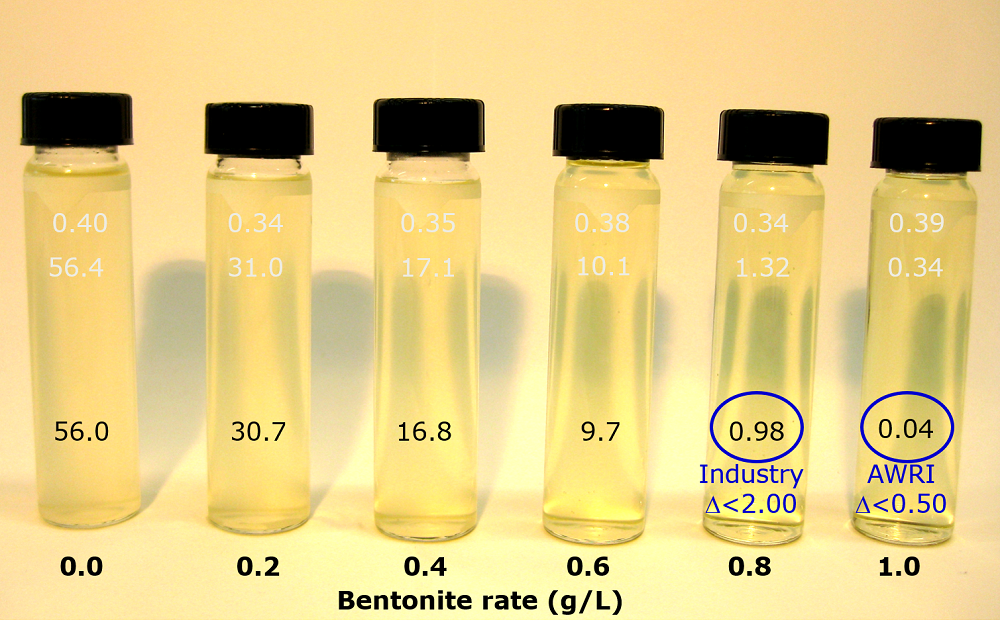

If a haze is seen in the fined heated wine, it is not stable and more bentonite is required. A turbidimeter can be used for more objective comparison of the turbidity in the heated samples. Determine the difference in NTU between the heated and unheated samples. Wines that exhibit a turbidity increase of greater than a given criterion for nephelometer turbidity units (NTU) after heating, as compared with the unheated control, can be considered to have failed the heat stability test. Some laboratories use a criterion of 0.5 NTU, but other practitioners in industry have indicated that a more reasonable criterion is 2.0 NTU. The bentonite rate of 0.8 g/L addition would be considered a pass result in this test below, with some labs considering a 1.0 g/L addition required for stability.

Example of the bentonite fining trial samples after heating. The difference of the NTU reading of each sample before and after heating is shown. Samples at bentonite rates 0.8 and 1.0 g/L would be considered stable, dependent on the laboratory’s criterion for heat stability.