Applying screw cap closures

A brief history of screw caps

The screw cap wine closure ‘Stelcap-vin’ (-vin implying use for table wines) was developed and trademarked in 1959 by a French manufacturing company, La Bouchage Mecanique (LBM) following social acceptance of their ‘Stelcap’ closure, commonly used for spirits and aperitifs. In 1970, Australian Consolidated Industries (ACI) obtained the licence to manufacture Stelcap closures within Australia, shortening the name to ‘Stelvin™’ in 1978 to identify the Australian development. Global trials with the screw cap were widely undertaken during the 1970s and were reinvigorated in the late 1990s by New Zealand winemakers and Clare Valley Riesling producers. The first AWRI ‘closure trial’ evaluated wine development of a 1999 Semillon wine sealed with 14 different closures including a screw cap closure, over a period of ten years. A total of eight major research or consortium closure trials (five white wines, two red wines, one sparkling wine) have been conducted by the AWRI since 1999. Additional resources on closure trials can be found in this information pack.

Screw cap use in Australia

Screw caps provide a consistent, near anoxic oxygen transfer barrier to wine compared to cylindrical closures. Wines sealed with screw caps exhibit less variation in wine development across different bottles compared to wines sealed with cylindrical closures. They are also much less likely to be affected by haloanisole taint. More recent developments have introduced screw caps with variable oxygen transfer rate (OTR), which allow controlled oxygen ingress if desired.

Entries to one of the largest wine shows in the world (the International Wine Challenge) from 2016 showed that 89.3% of Australian wines submitted were sealed with screw cap closures (n=1,322). The equivalent percentage for wines from all countries entered into that show was 26.3% sealed under screw cap (Wilkes et al. 2016).

Screw cap components

Screw caps consist of a metal (aluminium) casing that envelopes the external glass surface of the wine bottle neck. The screw cap has a seal that does not make contact with the internal surface of the bottle neck. The seal of a screw cap closure is by way of a disc that is compressed against the glass of the bottle neck rim. The disc requires a suitable liner material to form the seal with the bottle rim. The metal casing of the screw cap keeps the liner affixed, while also creating an easier opening mechanism for the consumer, and provides a tamper-evident seal, corrosion resistance for extended storage and a long skirt designed to symbolise the traditional wine capsule (foil). A shorter skirt option is also available.

Screw cap liners

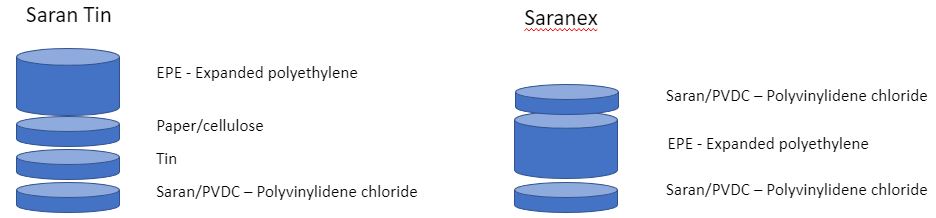

The initial development of the liner material for screw caps focused on creating a chemically inert liner facing that was food grade and compatible with wine. The material used for this purpose was polyvinylidene chloride (PVDC) which is now commonly referred to as Saran. Saran has been shown to be an extraordinary barrier against water, with chemical resistance to acids, and impervious to mould and bacteria. The liner market for screw caps has been dominated by two main materials that include Saran: Saranex and Saran Tin (or Tin Saran). Figure 1 shows a schematic of liner materials and their layered development. Each liner consists of three or four main layers, but can be made up of many smaller layers. An expandable polyethylene layer allows compression against the bottle glass when pressure is applied to the closure and liner. The Saran Tin liner, with a fine tin layer, was developed to reduce the gas transmission properties of the material, reducing oxygen permeability. The oxygen transmission rate (OTR) of Saran Tin liners is typically 0.00005-0.0005 cc O2/day, with the Saranex liner an order of magnitude higher at around 0.0001-0.001 cc O2/day. Saran Tin liners play a large role in the Australian and New Zealand wine market for wines sealed under screw cap. In the European wine industry, however, producers using screw caps tend towards Saranex due to the perception that wines sealed with Saran Tin can develop ‘reductive’ characters due to the very low levels of oxygen ingress through the liner.

Figure 1. Saran Tin and Saranex liner

Screw cap application

On a packaging line, screw caps are inserted onto the bottle and have both a downwards and sideways force applied on different parts of the closure to:

1) make the seal with the bottle

2) enable the cap to be broken and opened as well as resealed

3) enable the closure skirt to stay on the bottle neck once the cap is removed.

During screw cap application, a bottle is picked up off a bottle plate by a sealing head. A cap is added or pushed/dropped onto the bottle if using an automated system. As the sealing head rotates, a plunger/pressure pad is pushed down onto the closure on the bottle and exerts a top pressure on the closure and liner, or the redraw. Thread rollers push the sides of the closure into the free spaces or indents of the screwcap bottle finish thread. Tuck rollers crimp the metal under the screwcap thread or finish locking bead, so that the closure skirt remains on the bottle once the bridges are broken and top part of the cap removed. As the head goes up, the load decreases and the rollers retract. In-line optical inspection using image analysis can identify if caps are too high, if there is insufficient or malformed thread, if there are broken bridges, if rollers have cut through the closure or other non-conformances.

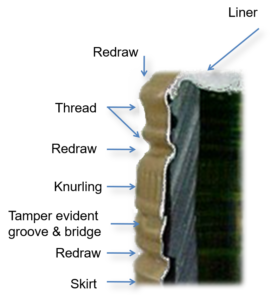

The term ‘redraw’ refers to the operation that ensure a seal between the bottle and the screw cap liner. For standard Bague Verre Stelvin (BVS) finish screw cap bottles, a pressure block containing a circumferential die is pushed down on the cap and the liner is compressed onto the surface of the bottle rim. The pressure block then continues to move down the side of the bottle a small distance, to create a seal between bottle and liner on both the top and the side of the glass finish. Redraw results in an elongation of the closure of approximately 0.5 mm (CE.T.I.E Bottling Guide No. 6 2016)

Figure 2. Screw cap redraw, thread, knurling, tamper evident grove, bridge and skirt

Screw cap ullage

An ullage space is required in order to allow enough volume for expansion of the wine during storage at 20–25°C. For standard Bague Verre Stelvin (BVS) finish screwcap bottles, the ullage space should be greater than 30 mm.

Screw cap removal

Stelzer (2005) details the following recommended ranges specified for torque force value (the sideway twisting force required to break the bridges of the screwcap) required to open screw cap closures from three different manufacturers:

| Auscap | 1.40 – 2.801 Nm |

| GlobalCap | 0.68 – 2.832 Nm |

| Péchiney | 0.90 – 1.813 Nm |

1Auscap specifies that values are dependent on variations in glass and application conditions.

2GlobalCap specifies this range providing that the test is carried out twenty-four hours after capping. The limits should be increased by 10% if testing is conducted immediately after capping.

3Péchiney states that these specifications are for a screwcap of 30 mm diameter.

References and further reading

Cetie. 2020. Bottling guide: Guide No 6: Metallic screw capping for still wines on BVS type glass finishes – with redraw. Rev 2. March 2020.

Institut National de l’Embouteillage, Association Francaise pour la Qualite tour Europe. 1991. Les Cahiers de la qualite en embouteillage. Cahier No 5: Maitrise de la qualite sur la ligne d’embouteillage. [Quality control on the bottling line.]

International Technical Centre for Bottling. Cetie: Free voluntary standards for glass and PET packaging.

Stelzer, T. 2005. Taming the screw – a manual for winemaking with screw caps. Grosset, J.; Brajkovich, M.; Forrest, J. eds. Brisbane: Wine Press.

Wilkes, E. 2016. Is it the closure or the wine? Wine Vitic. J. 31(6): 22-25.