Technical Note – Technical Review No. 253 August 2021

Introduction

There is increasing demand from both consumers and regulatory bodies to include information about the dietary energy content of wines either on wine labels or at an easily accessible location such as a linked website. Provision of this information requires a uniform method of measuring energy content to ensure that the information provided to consumers is useful, consistent and accurate. As is the case for most foods and beverages, it is not practical to measure the energy content of a specific wine product directly. Instead, the usual approach is to calculate the sum of contributions of individual components using published values for energy. In wine, in which water and alcohol typically make up 98% of the product, it is generally accepted that a valid value for energy can be calculated from the alcohol and the sugar content, as these two components contribute the vast majority of the energy.

Recently, questions have been raised about the possible energy contribution of other wine components such as organic acids, glycerol and protein, as well as wine additives, and whether they should be included in any energy calculation. Accurately determining the concentration of these components could require additional expensive analysis that is not typically conducted by production winery laboratories. This raises a secondary question as to whether measured values for these components are necessary, or if the relative variability in their energy content between wines is small enough to allow the use of generic values while still giving an acceptable estimation of energy content. This question must also be taken in the context of the increasing number of reduced and low alcohol products available on the market, where the contribution of the alcohol to the overall energy calculation is much less, leading to a larger relative contribution from other wine components.

To address these questions, data from the AWRI Commercial Services database was used to calculate the impact of different wine components on overall energy calculations. Because the available data on glycerol was relatively limited, an additional survey of 60 commercially available Australian wines (30 red and 30 white) was carried out. Thirty reduced alcohol and low alcohol wines were also sourced from industry partners in Australia to determine if the glycerol values for these wines varied significantly from those in the commercial wine survey.

Typical wine compositional values

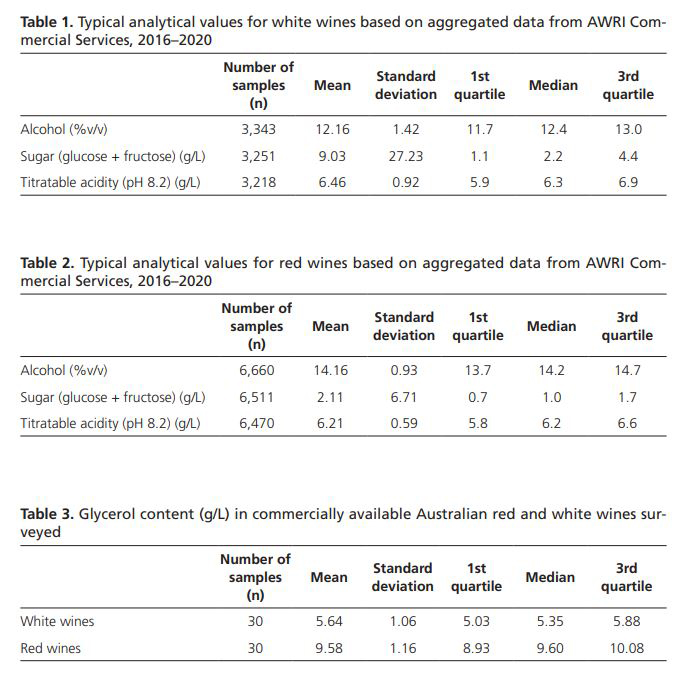

The typical wine values listed in Tables 1 and 2 for alcohol, glucose + fructose and titratable acidity are aggregated from around 10,000 wines analysed by AWRI Commercial Services’ NATA-accredited laboratory between 2016 and 2020. They have been categorised into red and white wines with rosé wines excluded. Rosé wines, however, can generally be considered to align with white wines for major compositional factors. For simplicity, sugar content has been taken as the sum of the concentrations of glucose and fructose in the wines, as these are the only significant sugars. Other sugars, such as the pentoses and sucrose, are typically only present at levels below 1 g/L.

Results from the glycerol analysis of the additional 30 white and 30 red commercially available wines are shown in Table 3. These values are consistent with results in literature and those in the AWRI Commercial Services database.

Of the 30 reduced/low alcohol wines sourced, only three were red wines and the remaining 27 were white wines. The reduced alcohol red wines (all <0.5%v/v alcohol) were found to have a glycerol concentrations of 5.9, 6.2 and 12.8 g/L, similar to the concentrations in equivalent red table wines.

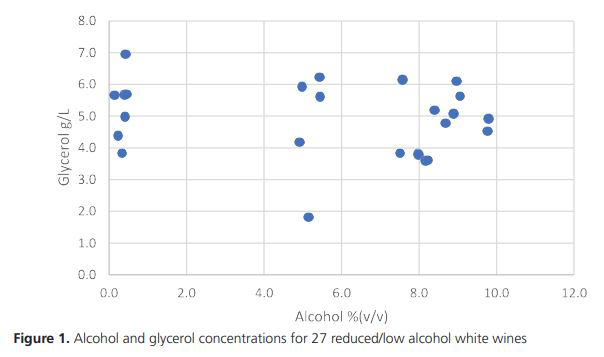

For the reduced/low alcohol white wines the glycerol content ranged from 1.8 to 7.0 g/L with a mean of 4.9 g/L and a median value of 5.0 g/L (Figure 1). Once again, these results are consistent with those seen for equivalent table wines. It should also be noted that reduced and low alcohol white wines tend to have higher sugar concentrations than typical white wines. Reduced alcohol products with alcohol levels above 0.5% were found to have a median sugar (as glucose + fructose) concentration of 11.3 g/L while those below 0.5% alcohol had a median sugar concentration of 49.2 g/L (see Tables 6 and 7). While these results are from a small sample set, they are in line with the general observations for low and reduced alcohol products.

Impacts on energy content

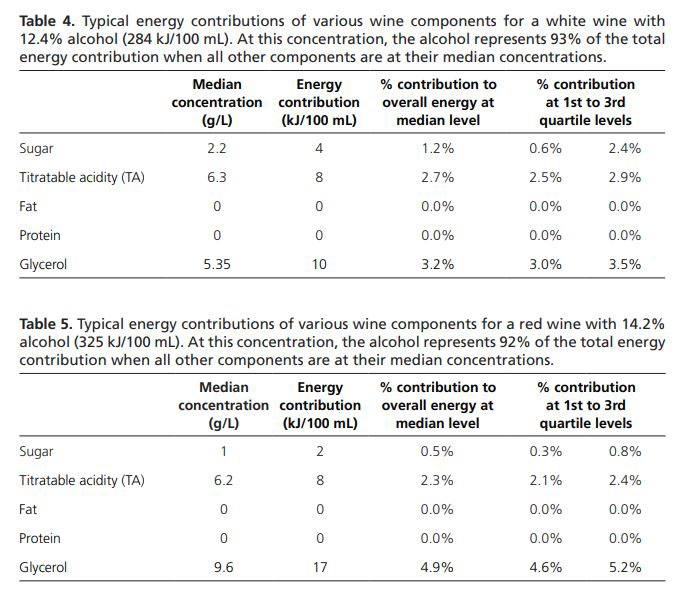

For a typical white wine with the median alcohol level of 12.4%, the energy contributions of a range of components are given in Table 4. The values in the last two columns show the relative contribution of each component to the final energy value if the concentration levels are at the 1st and 3rd quartile for that component. That is, these values show the impact on overall energy for the typical range of concentrations for that component.

Similarly, for a typical red wine with the median alcohol of 14.2% the energy contributions of the various components are given in Table 5.

In Tables 4 and 5, the values for fats and proteins have been set to zero as these components are rarely present in levels above 0.5 g/L in typical table wines and hence do not make a significant contribution to energy content (usually in the region of 1 kJ/100 mL).

Tables 4 and 5 show that the variation in the energy contribution between the 1st and 3rd quartile values for acids and glycerol is in the order of 0.5%. It is only for sugar in white wine that the typical range of values has an impact greater than 1%.

These calculations suggest that in the case of typical table wines it should be sufficient to use standard values for TA and glycerol in energy calculations, based on the median values for red and white wines. It is important, however, to note that the typical contribution of these components is non-trivial (5.9% for whites and 7.2% for reds) and consideration should therefore be given to their inclusion in the calculation of the overall energy for a wine.

Most wine production facilities would have a reliable knowledge of the sugar content of their wines for labelling and stylistic reasons. Hence it reasonable to assume that this figure would be available without extra cost and could be easily used in any energy calculation. Alternatively, consideration could be given to the approach of using standard figures for sugar based on classes of wine, such as dry, semi-dry, etc. as this would still give values that would have only a marginal effect on the overall accuracy of the final energy declaration.

Impact of components on low alcohol wines

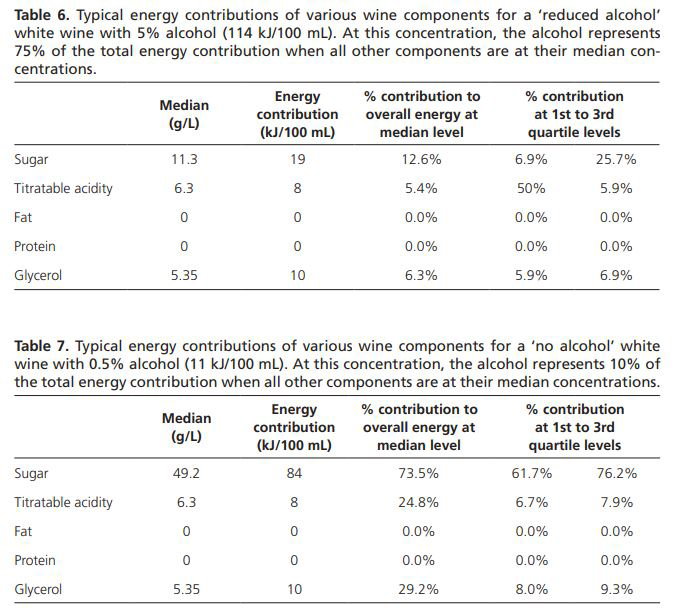

Tables 6 and 7 show the impacts of the different ranges of wine components on the energy content of a 5% and 0.5% v/v alcohol white wine. These alcohol values were arbitrarily chosen as representative of low alcohol and no alcohol products, respectively.

The most obvious impact of the lower alcohol concentrations in these products is the significant reduction in overall energy content, even if it is somewhat offset by the higher sugar contents typically seen in these products. This highlights the dominant effect of alcohol on energy content, with the 0.5% alcohol wine having ~10% of the energy content of a typical white table wine if the sugar contents were the same. Also apparent is the increased impact of sugar. Even using the lower sugar values typically found in table wines, moving from the median value of 2.2 g/L to the 3rd quartile value of 4.4 g/L sees a change of 5 kJ/100 mL, an ~11% change. The impacts for sweeter wines are much more significant, and at just 7 g/L the contribution to the energy content of the sugar component would outweigh that of the residual alcohol in the product. For reduced alcohol products with ~5% v/v alcohol, the impact of sugar would not outweigh that of the alcohol until around 70 g/L of sugar.

The impacts of the typical range of values for titratable acidity and glycerol on overall energy content are still relatively minor, even for wines with alcohol levels as low as 0.5% v/v, representing a combined change in energy content of less than 5% across their typical ranges. Given that in a number of markets, including the EU and the US, the proposed allowed variance from the actual value for energy labelling is 20%, it seems that using typical energy contributions for TA and glycerol for a given wine style would still give a satisfactory result without the need for extra analysis. The same is also true of other minor wine components such as protein, which, even at an unlikely value of 0.5 g/L, would contribute less than 1 kJ/100 mL, or less than 1% of the total energy content of a 0.5% v/v alcohol wine.

Conclusions

Based on this analysis, a number of recommendations could be made to ensure the consistency of energy labelling within the wine sector:

- Energy content calculations for wines (both table wines and reduced or low alcohol wines) should be made using measured values for alcohol and sugar and set values for glycerol and titratable acidity (as a proxy for organic acids).

- The set values for glycerol and titratable acidity for red and white wines could be defined by their median values determined from the AWRI wine survey (Table 3).

- Other wine components and additives can be generally ignored as not contributing significantly to the energy content.

- The validity of these assumptions should be reviewed every 10 years by reference to survey data to ensure that the introduction of new technologies or additives has not significantly changed the typical values.

- The energy density figures used for the calculation of energy values for the label wines and wine products in Australia should be those published by FSANZ (see Appendix).

The adoption by Australian regulators of a 20% tolerance for energy values on labels and other communications is worthy of consideration as it would align Australian labelling with other jurisdictions, including major export markets. This would allow the adoption of standard energy content values for classes of product rather than having different values calculated for each individual wine, reducing consumer confusion and increasing efficiencies for producers.

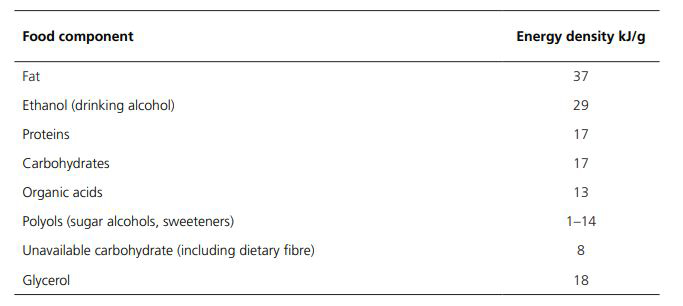

Appendix

For the energy calculations in this article, the following energy density values were used, based on values published by Food Standards Australia New Zealand (FSANZ).

Acknowledgements

This work was supported by Australia’s grapegrowers and winemakers through their investment body Wine Australia, with matching funding from the Australian Government. Accolade Wines, Pernod Ricard Winemakers, Treasury Wine Estates and Vinpac are thanked for donations of reduced alcohol wines.

Dr Eric Wilkes, Group Manager – Commercial Services, eric.wilkes@awri.com.au.